Xinjiang is rich in lithium resources and is one of the dominant mineral resources. The main types of lithium deposits in Xinjiang are hard rock lithium deposits and salt lake brine type lithium deposits. They are mainly distributed in four mineralization belts, namely West Kunlun-Karakunlun Lithium polymetallic mineralization belt, Altai Mountain lithium polymetallic mineralization belt, Altyn lithium polymetallic mineralization belt and East Tianshan lithium polymetallic mineralization belt. With the development and popularization of lithium batteries, Xinjiang's lithium deep processing industry is developing rapidly.

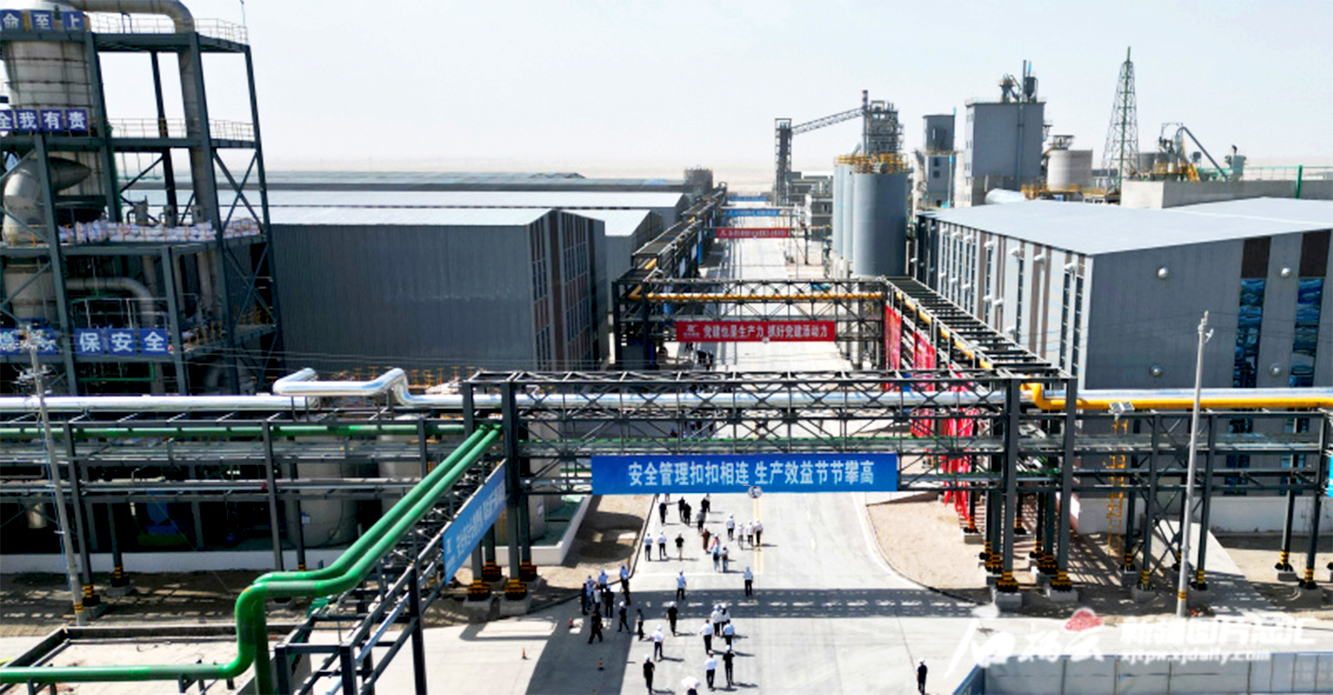

The first phase of the lithium carbonate project with an annual output of 120,000 tons was successfully put into operation, injecting new impetus into the development of Xinjiang's new energy battery industry chain and cluster. At present, the new energy project has a set of integrated drying and cooling system with advanced equipment technology, and has established a perfect testing means and quality assurance system.

In order to meet the high quality needs of customers, China Forrest Engineering conforms to the market trend, research and development of composite boiling bed drying and cooling integration technology, through the role of high-speed air flow, so that the material is in a fluid state, in this state, the material particles roll up and down in the bed, and with the hot air flow for effective heat and mass transfer, so as to achieve the purpose of drying.

The combined boiling bed drying and cooling technology has a larger working space in the main building, and can be equipped with intelligent control system under the condition of easy maintenance, easy operation and high flexibility. At the same time, it is also equipped with a large fluidized bed host, which reduces the investment cost and improves the drying efficiency.

The equipment achieves a small footprint, efficient heat transfer, convenient production of sodium sulfate materials, while taking into account high standards of environmental emissions. Its high heat transfer coefficient, large heat transfer area and other characteristics, can provide uniform drying and good particle integrity. The material stays in the fluidized bed for a long time, which is conducive to the full drying of the material. Using cyclone and wet two stage dust removal, the dust removal efficiency is high.

Build green ecology and create industry benchmark. Forrest Engineering with high efficiency, high precision, high environmental performance and other core advantages, won the industry customers highly recognized. Forrest Engineering will continue to help new energy materials "occupy the market with quality, stabilize the market with credibility" business purpose, to serve customers.