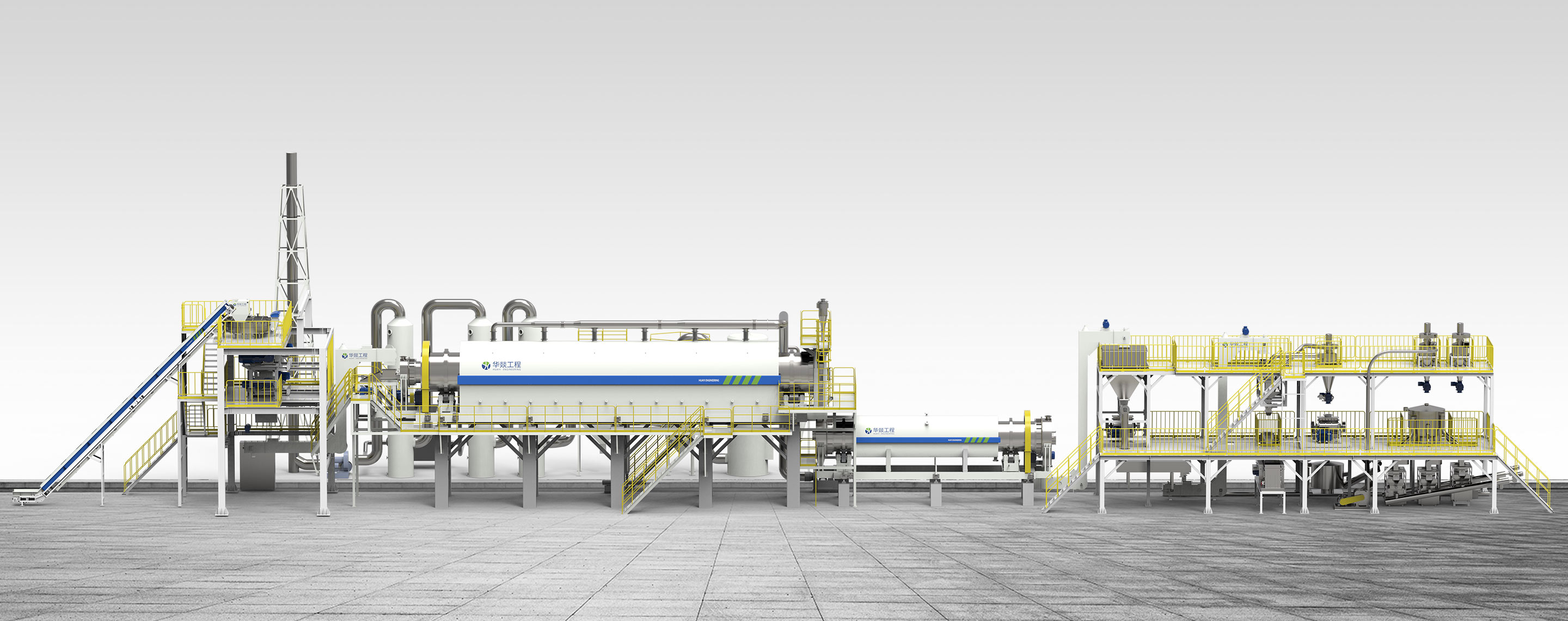

Lithium-ion Battery Recycling

Provide customers with overall solutions in design, manufacturing, installation, commissioning, technical services and training, and after-sales services

Lithium-ion Battery Recycling

Provide customers with overall solutions in design, manufacturing, installation, commissioning, technical services and training, and after-sales services